|

|

|||||||

| Firth Brown Solid Taps | |

|

Quality Chaser Company is pleased to announce an agreement to represent Firth Brown Tools.

Firth Brown has been manufacturing exceptional tooling in Cambridge, Ontario since 1921. Their tools are designed and engineered on-site under ISO 9001 quality certification guidelines. Primary products of the Firth Brown Company are solid high-speed steel pipe taps, nib taps, bent shank and spiral point taps. A variety of premium material options and surface treatments are also available. These special taps are used in applications such as automotive, lead-free brass valves and fittings, pipe and fastener couplings, construction grade nuts and other demanding applications where high production and superior performance are required.

You can submit a Request for Quote on

the E-Mail page, or...

Contact our Customer Service for quoting requirements and details.

|

Version 1.4 of Quality Chaser's colorful Product Guide on CD-ROM includes the most up-to-date information available, plus:

Visit the E-Mail page and request your free copy today. You can also download a copy right now from the Download page. |

|

|

Quality

Chaser offers

Oster

style dies in a

broad range of symbols and sizes.

Further information can be found on the Oster page, or get a copy of our Oster Product Guide in .pdf format from the Download page. ... or just give us a call. |

|

|||

| Chasers manufactured by Quality Chaser Company fall into two distinct categories. | |||

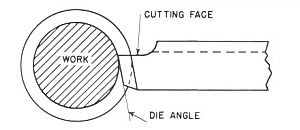

| MILLED FORM chasers are the most common and are identified by a straight relief or die angle. The die angle will vary depending on diameter and pitch. As you can see in the diagram, the die angle is required for clearance of the work piece diameter and to facilitate freer cutting action at the cutting face. When regrinding milled form chasers, material is removed from the chamfer in order to hold the centerline position of the cutting action. |  |

||

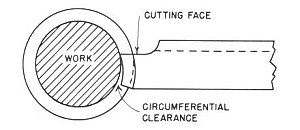

| TAPPED FORM chasers are manufactured on a concaved surface and have a distinctive concave profile. In contrast to the straight die angle on the milled form chaser, the tapped form chaser has "circumferential clearance" that serves the same purpose. The tapped form chaser has one major advantage over its milled form counterpart, however. The cutting face of tapped form chasers can be reground without regard to center height, thereby allowing for more regrinds and longer tool life. |  |

||

| Contact

our customer service department with your specific requirements, to

determine which chaser form will best enhance your threading

performance.

|

|||

Call for information. |